The Ex motor protection (hazardous areas) has been designed to get in one device the ability to protect one electric tri-phase motor in zones with explosives atmospheres (hazardous areas) and to start and stop that motor.

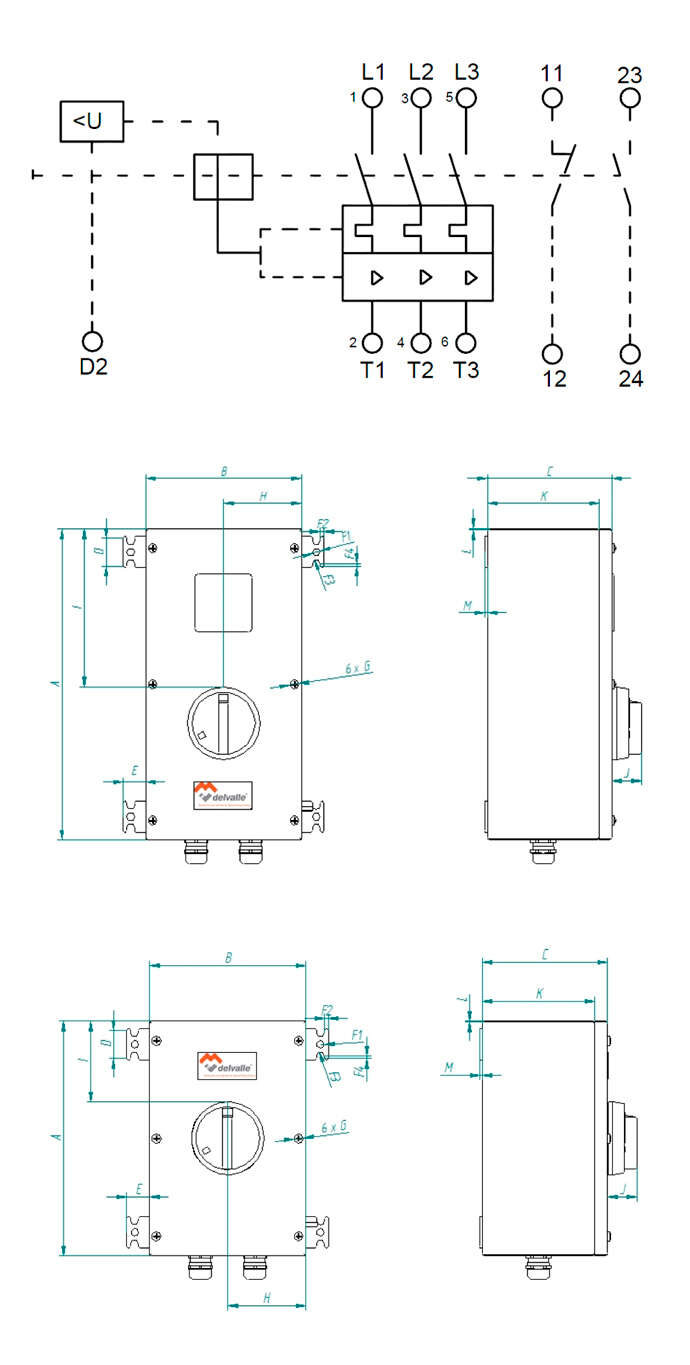

It’s formed by two components: Motor protector, and a selector controler with starts and stop.

The design has been made on a waterproof and antirust enclosure with AISI 304L stainless steel. This design way allows us to use this device in protected spaces with high explosion risk, getting this manner, the “Ex e” and “Ex d” protection types in potentially explosive atmospheres of dust and gas.

It can be used in any industry considered as an industry with explosive atmosphere in dust or gas places, like be oil & gas, chemistry, petrol chemistry, petrol, offshore industry, etc.

The Ex motor protection has been designed to get in one device the ability to protect one electric tri-phase motor in zones with explosives atmospheres and to start and stop that motor.

It’s formed by two components:

•As internal component it just has one motor protector, which protects the motor against heavy electric problems, like short-circuits, overloads and motor or circuit phase failures.

•It has a selector, the only one control component. It starts the motor with ON position (1) and stops it with OFF one (2).

The design has been made on a waterproof and antirust enclosure with AISI 304L stainless steel. This design way allows us to use this device in protected spaces with high explosion risk, getting this manner, the “Ex e” and “Ex d” protection types in potentially explosive atmospheres of dust and gas.

It can be used in any industry considered as an industry with explosive atmosphere in dust or gas places, like be oil & gas, chemistry, petrol chemistry, petrol, offshore industry, etc.

· A really important advantage about using this device, is that it can work with a lower temperature than the ranges say, being possible to work, in some many unfavourable places, with -25°C in gas group IIB

· This Ex motor protection’s design avoids placing fuse to protect the electrical line against short-circuits or over loads.

· Thanks to this device, the motor useful life will be longer, because it’s protected against many electric problems.

· The enclosure can be manufactured with AISI 316L stainless steel.

ATEX directive and regulation:

- ATEX directive 2014/34/EU

- EN 60079-0:2012

- EN 60079-1:2007

- EN 60079-7:2015

- EN 60079-31:2010

IECEx regulation:

- IEC 60079-0:2011

- IEC 60079-1:2006

- IEC 60079-7:2015

- IEC 60079-31:2013

Enclosure regulation:

- IP regulation (IP65): IEC 60529

- IK regulation (IK10): IEC 62262

Low voltage directive and regulation:

- Directive 2014/35/UE

- EN 61439-12011

- EN 61439-22011

APPLICATIONS

Specially designed for the following areas where facilities require additional safety atex:

- Oil & Gas.

- Offshore & High sea.

- Industry and automation.

- Chemical and refineries.

- Pharmaceutical.

- Maritime and port.

- Fieldstations.

- Food & Beverage.

- Paper industry.

- Air transport.

- Nuclear and renewable.

And in general, hazardous areas and explosive atmospheres where flameproof equipment are necessary.

· Low voltage auto trip which switches off the motor if there was a fallen voltage.

· Auxiliary contact normally closed and normally opened.

· We recommend adding an ammeter to check the current inside the circuit.

· Box made in AISI 316L stainless steel to marines or highly corrosive places.

· Possibility of using it with low temperature -25°C with IIB gas group.

· Cable glands available in any size and thread.