This Ex motor magnetic starter (hazardous areas) has been designed to guarantee the correct operation and the protection of electric motors in high explosion risk zone.

It’s used to control the electric motor switching on and switching off, besides to protect it against overloads thanks to the thermal relay.

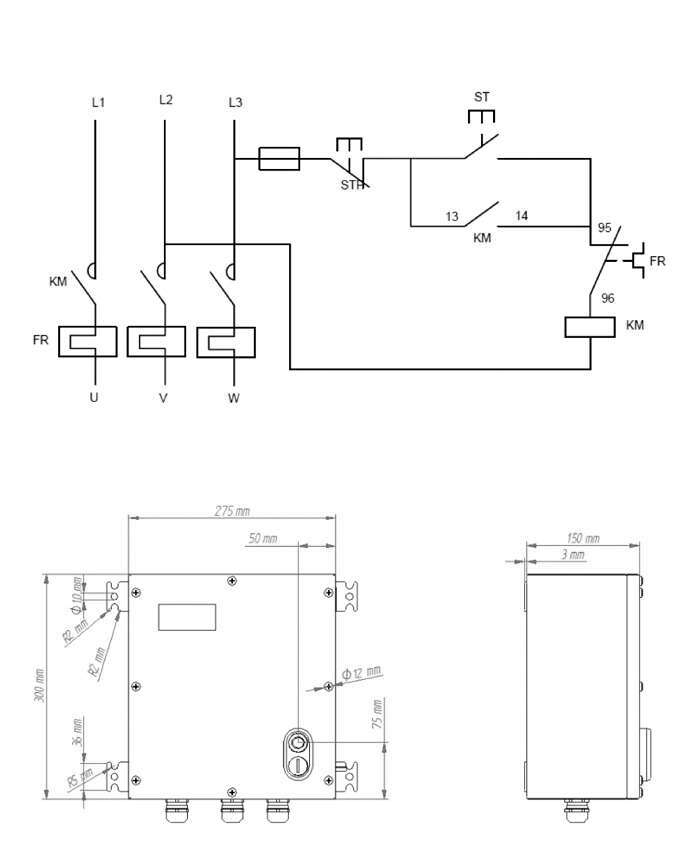

The device has some components: Internal components (Contactor & Thermal relay) and Control components ( Double butto)

The Ex motor starter components, are protected inside of an ATEX & IECEx enclosure, made with sstainless steel AISI 304L.

This Ex motor magnetic starter has been designed to guarantee the correct operation and the protection of electric motors in high explosion risk zone.

It’s used to control the electric motor switching on and switching off, besides to protect it against overloads thanks to the thermal relay.

The device has some components:

•Internal components:

Contactor: allows or doesn’t allow the current to go through the circuit.

Thermal relay: switches off the circuit when the current consumed by motor is higher than the current allowed, avoiding this way the motor coil get burned.

•On the other hand, the control components, it has a double button on the cover, which function is switch on the motor with ON position (1) and switch off the motor with OFF position (0).

The Ex motor starter components, are protected inside of an ATEX & IECEx enclosure, made with sstainless steel AISI 304L. This enclosure has a specific design, being antirust, waterproof and with IP66 protection. It has a protection “Ex e” and “Ex d”, being possible to use it in zones with high explosion risk outdoor and rust.

· This Ex motor starter allows a faster switching on after a thermal relay’s trip.

· It will have a longer use thanks to thermal relay, which avoids sudden motor stops and therefore machine stops.

· It’s possible to get the coil with low voltages, controlling high capacity motors with a low tension circuit.

· There are so much voltage and current possibilities to choose the Ex motor starter.

· It can be manufactured with AISI 316L.

ATEX directive and regulation:

- ATEX directive 2014/34/EU

- EN 60079-0:2012

- EN 60079-1:2007

- EN 60079-7:2015

- EN 60079-31:2010

IECEx regulation:

- IEC 60079-0:2011

- IEC 60079-1:2006

- IEC 60079-7:2015

- IEC 60079-31:2013

Enclosure regulation:

- IP regulation (IP65): IEC 60529

- IK regulation (IK10): IEC 62262

Low voltage directive and regulation:

- Directive 2014/35/UE

- EN 61439-12011

- EN 61439-22011

APPLICATIONS

Specially designed for the following areas where facilities require additional safety atex:

- Oil & Gas.

- Offshore & High sea.

- Industry and automation.

- Chemical and refineries.

- Pharmaceutical.

- Maritime and port.

- Fieldstations.

- Food & Beverage.

- Paper industry.

- Air transport.

- Nuclear and renewable.

And in general, hazardous areas and explosive atmospheres where flameproof equipment are necessary.

· The rated current of AC contactor can be chosen between: 12, 25 and 38A.

· The coil service voltage is between: 24, 36, 48, 110, 220-230 and 380-400V.

· The setting range of thermo relay is really large: : 0.1-0.16, 0.16-0.25, 0.24-0.4, 0.4-0.63, 0.63-1, 1-1.6, 1.6-2.5, 2.4-4, 4-6, 5.5-8, 7-10, 9-13, 12-18, 16-24, 23-32 y 30-38A.

· The enclosure can be manufactured with stainless steel AISI 316L to marines or highly corrosive places.

· Cable glands available in any size and thread and they can be with stainless steel.